Recent trend for the Screw Press

1 Change of Customer Needs

So far, hot forging becomes high accuracy and the background of screw press feature that avails to high speed forming capability accelerates screw press?f usage in warm forging field resulted in increasing demand for higher precision in the screw press, too. Following is the requirements recently we were pointed out

(1) Even Forming Energy

The screw press consumes all flywheel energy during stamping and stamping pressure amount is adjusted through controlling flywheel revolution (quite similar with controlling forming pressure through adjusting hammer’s descending speed). In conventional friction driven system (friction screw press), introduction of encoder to detect flywheel revolution for controlling revolution energy improved forming pressure repeatability drastically. However, heat change in friction clutch portion changes starting characteristics when the clutch is activated (angle in starting curve varies). The point-out stresses that the deviation in clutch release timing causes to change in certain amount of energy. For example, during complete automatic operation, practically there is no energy change in normal operation, however, if the machine has to have downtime as a result of frequent machine errors, the clutch board (friction wheel) gets cool and causes to change the energy right after restarting.

(2) Longer Life for Clutch Lining

Nature of linear contact at the friction potion requires flexible and heat durability as lining material. Usually, natural leather (e.g. cow, buffalo) is used. Heavy leather proofing can prolong the life, however, the clutch power decreases. While without proofing, good response and fewer scattering in stamping pressure are available, however the life shortens. The resolution of this problem is important because the machine must not stop during continuous operation. Reduction of maintenance cost is strongly required.

(3) Optimized Machine Operation Efficiency

The screw press is powerful because it uses all flywheel energy during forming. On the contrary, when small work piece is formed with large machine, the machine needs to reduce flywheel revolution (energy) to avoid overload. Please note that the machine also has this disadvantage of reduction in machine operation efficiency in small work piece.

(4) The servomotor driven screw press is the one which resolved almost all of the requirements.

(a)

No scattering in flywheel revolution and energy for every stamping operation. The servomotor directly controls the flywheel revolution and basically it can provide constant value right before stamping. The variance of press power under automatic operation is shown on the figure with the comparison of press power variance of conventional (competitor’s) friction screw press and servo driven machine.

Remarks: In case of the servo driven machine, measured rum speed prior to the forging is nearly even.

On the attached graph of press power, the load variance of servo machine comes out including the variance of material volume, material heating temperature, lubrication condition, etc., a viewpoint is possible to understand that the load variance on the graph does not represent the variance of press energy.

(b)

No consumable parts because of no friction driven system (On the machine which uses servomotor in general use, connecting belt between motor and flywheel wears out but its life lasts for several years and is inexpensive to procure.

(c)

In case of a small press power set, a program is automatically applied to slow down the slide speed for softly hit after the slide is approached with high speed, so time length of one process will not be longer time in case of forging a small piece with large press. In addition, ascending acceleration, speed reducing and stopping at the uppermost are done quickly and is operated without any adjustment.

2 Newly Developed Screw Press, Its equipment and Forging Method

The conventional friction clutch driven type ended its historical role by the introduction of servomotor direct driven system described below. Four-disc Type super rapid friction screw press and double screw type were developed, however, these are basically replaced by the servo driven type. Accordingly, the friction clutch type will not be touched in this section and is left to the equipment description in the sequel.

-

(1)

Servomotor Driven Screw Press

-

(2)

Vertical Upset Screw Press

(Servo Driven) -

(3)

Screw Press for Cored Forging

-

(4)

Screw Press for Simultaneous Both Axes-end Upsetting

-

(5)

Screw Press with Automatic Vertically Divided Tools Equipment

-

(6)

Thin Material Hot Forging and Magnesium

-

(7)

Development of Magnesium Raw Material

-

(8)

Semi-Closed Die Warm Forging System

-

(9)

Trimming Device

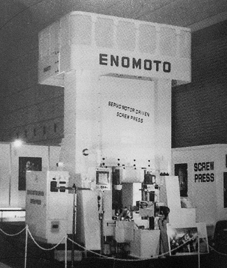

(1) Servomotor Driven Screw Press

The screw press for forging has been developed in the run-up tothe world as multipurpose servomotor driven type.

Basically, a servo press is a machine which connects a motor directly to crank shaft and controls the position, speed and torque of slide at every moment, however, our developed machine makes servo driven to control flywheel revolution energy and the total energy is consumed at the time of processing just like the conventional friction screw press, and is possible to produce nominal

3000kN with 30kW servomotor as the case may be.(If it is a direct axis coupling type, 700~800kN is at most with a 30kW motor.)

Pressure implied is the instantaneous impact of pressure which is the same as the conventional friction driven type, and time correcent trend for the Screw Press responding control for time, pressure torque and pressure speed are not possible. Acutually, there is no difference with conventional type which consumes all flywheel energy and powerful forging is possible.

Servo driven is introduced in an upsetting screw press with slide ascending then forging as well as general forging equipment with the slide down ward stroke, however, all of the screw press machines mentioned after are becoming servo driven type. Features are as follows

300 VES

400 ZES

Less Maintenance

There is no clutch equivalent component since it is not a friction driven. A break does not operate during normal running and the motor itself stops a slide. Mechanical brake is only for emergency use, such as power failure so the brake lining does not wear after long time of operation. There is no friction axis disc shaft as in the friction driven machine which means no worn parts exist. Since the number of components is extremely small, total maintenance effort is extremely reduced.

Save Energy

The motor does not rotate always except operation. (The motor rotates all the time in friction type.)

After one cycle of process completes, the motor itself performs slide stop action from ascending to stop and the motor generates regenerative power to feed the power to the factory. (Power consumption at the factory is reduced that much of power generated.)

In comparing to the friction type, 30~50% of power is reduced with respect to that of conventional friction type as total save energy effect.

Able to Reduce Slide Speed and Wide Range of Objective Work Size

Since the slide speed reduction action of a slide after the acceleration is possible by direct drive while the friction driven type is impossible, the processing time for one cycle will almost not differ for forging a small work with large press which brings out the epoch-making result of "The Greater Embraces the Less".

By setting the press energy, the slide is accelerated to moving downward. At some point of down stroke position, slide speed will be reduced then press material at the pressure previously set.

All are done automatically. Since the flywheel energy right before the press is highly even, precise forging is realized.

Excellent Running Response

Running response is excellent since there is no time loss of clutch response because it is directly driven. The setting of tool becomes easy in jog running mode rather than inching.

It is possible to apply static pressure continuously and there are machine types with

adjusting slide position and speed control capabilities.

(2) Vertical Upset Screw Press (Servo Driven)

Photo-1 Incremental Forging material

Changed the name previously called [Vincent Type Screw Press] for easy understanding of machine. This type of screw press has the unique structure of pressing after a slide lifted up by screw mechanism and has the big merit of forging only the top part of long material (upsetting). This has been preferably used for hot forging on top part of thick or long bolt (hexagonal or cap screw) and is developed as modern press of servo driven eliminating skillful operation. (Before the servo driven machine, friction driven type with electronic/pneumatic control type had been developed in favorite reception, however, almost all of produced machine are changed to servo driven type since its completion of development.)

Upsetting method is the deformation processing by forging axis-end enlarged. Basically, paying attention to only two points, one for enable to insert long material into the machine and another for taking processing method not to be buckled, are enough.

Many kinds of products, such as axial gear, bolt, rear-axle shaft, engine valve, halfcrank for motorcycle, etc. are forged. Since the deformation processing requires attention of not to be buckled for long material, sequential forging of 3~5 processing steps are performed generally. (Photo-1)

Photo-2

Servomotor driven vertical upsetting

screw press

Photo-3

3 processing forging top die sifting device

A header of mechanical press or transversal upset machine has been used for upsetting before, and occupied the position of expensive forging processing since it required tool for each process, transfer device and clamping device. The machine developed by our company was generally called [Vincent type Friction Press] and has been used for forging thick hot bolt or railroad spike and is now able to perform precise forging by servomotor driven. (Photo-2)

The forming energy of this machine is large enough. For example 3000kN press, two inch size hexagonal bolt head can be forged.

●The slide of this press forges with the motion, from bottom to top direction. This looks like a Counter Blow. The stroke length is able to be designed much longer, such as 600~800mm, and is able to put long size material into the die. In addition, the material length is adding unlimited by the Lower Die shifting device with digging deeper depth of pit.

●Transfer of material is not required. After the material is inserted, forging is performed automatically for 1st,2nd and 3rd stroke with top Die changing for each stroke. Each pressure implied is able to be set individually at arbitrary to repeat the forging. When the material is inserted in the lower tool and after pushing start button, forging is performed until the last process automatically. Of course the machine is fully automated by installing loading and unloading devices. (Photo-3)

Presumable complicated operation by skilled operator is mode translated for repeatable. For example, it includes halfway stop during slide ascending, restart, forging, slide return, knockout and material insertion with slide pullup a little high, etc. Contact of signal transmission at any position of slide stroke is possible.

●Tool cost is inexpensive. The required number of die gets small since the lowerdie requires only one and two to four for upper die. The total thickness of each upper and lower die is possible to be set arbitrary since there is no mechanical lower-dead-point in the press (we call it pressure end because the forging applies after lifted) which turns out that die corrective re-sinking does not matter even if they are arbitrary value.

●Die change time is short. There is no Bottom/Top dead center and the combined thickness of tools is not required to take into consideration. Differing from mechanical press, the adjustment of lower-dead-center is not necessary. Only required thing is to adjust press energy for each process. It is not impossible to produce fair quality item from the beginning if it goes smoothly.

●There is no longitudinal fin on products because the tool is not split type.

●The press has no friction clutch since it is direct drive type. Brake device is something like Parking Brake and lining lasts permanently without any replacing maintenance.Stop action at the end of one cycle is done by the motor itself and regenerative power generated at the time saves 30~50% of electric energy.Slide speed reduce during one cycle process, which is not possible with friction clutch type, is possible and time required for one process is almost constant/most quick for both big power/small power operation.There is no press power variance since it is direct driven type.

●Relatively cheap upset forging is realized with approximately half or less initial cost by comparison of mechanical transverse type upset machine, tool cost reduction and maintenance cost reduction. The advantage of this type for upset forging structural design is that the stroke is possible to be long, fine adjustment of material thrusting amount from bottom die surface is easily performed (no need of replacing pin), other drive source, such as hydraulic, is not necessary since knockout is performed by hammering, knockout bar or pin is easily pull out, etc., and this type has an unique structure with respect to any other press machines and general screw presses. It is expected that the application will be expanded in future. In addition, the equipment which introduced trimming mechanism into one of the upper tool shifting device is under patent pending.

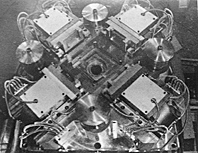

(3)Screw Press for Cored Forging

This screw press was developed to aim at improvement of material yield, post process elimination or reduction and shift from casting equipped with dedicated complex equipment. A special equipment (called cored equipment or Sub-press) is installed on bed and the device employs method of hole forming pin(s) (1~4 each) diving horizontal direction to the side surface of material after the slide goes down and both upper and lower tools clamp material. The special equipment is removable and the machine functions as ordinary screw press. Common usage for the machine is for hot forging of brass, copper and aluminum material. The cored equipment consists of cushion part of bolster unit, mechanical cam mechanism for conversion of the cushion’s vertical movement to horizontal one and built-in knockout equipment. The cushion part can also be installed in the upper tool as the hollow is required in the upper tool. Because of the mechanical cam mechanism, pin breakage is avoidable for synchronization between tools’ vertical movement and horizontal pushing pin movement is made. Also, there is no variance of push-fit depth of horizontal pin because of compressing down to the stroke end of the cushion based on the structure of screw press. In case of mechanical press, the push-fit depth varies due to the variation of die height dimension at the lower limit of slide caused by the frame stretch because of the existence of the mechanical lower-dead-point. The flywheel energy is designed larger since the amount of energy to deform material requires large amount, however, fundamental structure is the same as general type of screw press. There is a fully automated machine, a servo driven screw press equipped with an auto hand with un-loader and a heating furnace in set.

Cored Forging Device Bed

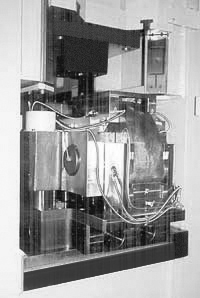

(4)Screw Press for Simultaneous Both Axes-end Upsetting

Upsetting equipment for both axes-end

simultaneously

The screw press furnishes with upsetting equipment for both axes-end simultaneously. Basically, it is a variation of the former cored forging equipment with only two directions and it’s rigidity is enhanced to secure large pushing energy. Generally speaking, complex processing is required in case of inflating both ends, starting with upsetting on one end of axis, then forge another end of axis by using divided tool, of course, those are hard to be automated. By using this machine, upsetting of both ends is forged at once, which gives big merit.

(5) Screw Press with Automatic Vertically Divided Tools Equipment

Automatic Vertically Divided Tools Equipment

The screw press furnishes with block instrument. Press operation is made to push press pins from up and downward after closing or opening movable divided tools horizontally and automatically. Tool securing mechanism prevents tools’ opening during press operation. The block instrument that squeezes and blocks longitudinal material is asking for a patent.

(6)Thin Material Hot Forging and Magnesium

Magnesium Thin Plate Hot Forging Sample

In recent sheet metal press field, there is a trial to heat thin material and change thickness point to point flexibly. However, ordinary mechanical press has the lower-dead-point and the frame deformation that restricts the thin material press capability. In case of hydraulic press, forming is unsuccessful without large scale of capability and pressing time getting longer, and there are defects of material temperature decreasing and short life time of tool. On the other hand, since the screw press has no lower-dead-point, these jobs can be seen as a pattern of coining and you don't need to think about frame deformation. We believe that the screw press is the most appropriate press machine. The photo shows excellent feature application of the screw press on hot pressing of Magnesium thin sheet to perform backward extrusion and boss forming.

(7)Development of Magnesium Raw Material

Magnesium rod or pipe is capable to be produced by hot extrusion after scrapped Magnesium chip being compressed, however, more excellent result has been obtained by performing so-called [Rice Cake Pounding] to attempt miniaturization of crystal grain of raw material before final chip compression.

After compresson of Magnesium chip in lower die by high speed impact pressure with flat punch, the flat punch is replaced by a point punch and is thrust down into the comptressed Magnesium chip.

Then, compress with a flat punch. After repeating this process several times, turn over the lower die and perform point punch extrusion and flat comptesson for several times again.

This process brings miniaturized crystal grain to be high-strength extruded rod stock. High speed performance of screw press brings about an effect.

(This matter was taken in as the R&D Operation of Application, University-launched, 2003, and the joint experiment have been made with the Tokyo University as well as with several companies.)

(8) Semi-Closed Die Warm Forging System

Samples of Semi-Closed Die Warm Forging by Createc Mold

Forming speed of screw press is extremely high, 500~1000mm/sec, and contact time of tool with material is rather short, which maintains longer life of tool. More important thing is that it is possible to reduce pressure load of tool by synergistic effect of deforming temperature generated from high speed forming and initial temperature of raw material which brings material stretched into narrow corner of tool before the material temperature goes down.

The semi-closed die warm forging system by CREATECH Co., Ltd., the substantial company in this area, and both software and hardware for screw press are provided.

(9) Trimming Device

A Vertical upset screw press is able to replace maximum three each of upper tool with upper shift device and a trimming device is equipped in one out of three. Forging is done at the first (and the second) stroke(s) and side burr (fin) is trimmed by the replaced upper tool. This has been employed in the servo driven machine since this method is able to adjust slide speed and stop position precisely.